Understanding Repmold in Modern Manufacturing

Repmold is a manufacturing method used to create molds by copying an existing master shape. The method focuses on speed, accuracy, and material efficiency. Industries use repmold when they need reliable molds without long production delays. Repmold refers to a structured replication workflow. The workflow converts a digital or physical master into usable production tooling.

Why Repmold Exists

Traditional mold making takes time. It also uses high-cost machining and large material blocks. Repmold exists to reduce these limits. Manufacturing studies show that replication-based tooling reduces setup time and waste. This makes repmold suitable for fast-moving product cycles.

How Repmold Works Step by Step

Creating the Master Model

To start repmold, manufacturers prepare a master model. The model defines the final part shape.

The master can come from:

-

A 3D printed prototype

-

A scanned physical part

Computer-Aided Design ensures the geometry is accurate.

Preparing the Mold Base

To prepare the mold base, technicians select compatible materials.

These materials accept fine details from the master.

Common mold base materials include:

-

Tooling resins

-

Composite polymers

-

Reinforced plastics

Replicating the Shape

To replicate the shape, the master is placed into the mold base material.

The material flows around the master and captures its geometry.

This step transfers:

-

Surface texture

-

Dimensions

-

Edge details

Curing and Stabilizing

To stabilize the mold, the material undergoes curing.

Curing improves strength and thermal resistance.

After curing, the mold becomes ready for controlled production.

Testing and Validation

To confirm accuracy, manufacturers test the mold.

Test parts are produced and measured.

Validation checks:

-

Dimensional accuracy

-

Surface quality

-

Repeatability

What Repmold Is Used For

Repmold is used to create production-ready molds. It does not create final consumer products. It creates the tools that make those products.

Common Manufacturing Processes Using Repmold

| Manufacturing Process | Repmold Role |

|---|---|

| Injection molding | Tool replication |

| Resin casting | Mold creation |

| Low-pressure molding | Cavity formation |

| Composite forming | Shape transfer |

Industries That Use Repmold

Repmold supports industries that value speed and precision.

Automotive Industry

Automotive suppliers use repmold for:

-

Interior panels

-

Clips and brackets

-

Functional housings

Repmold reduces downtime when tools need replacement.

Medical Manufacturing

Medical companies use repmold for:

-

Device housings

-

Diagnostic components

-

Disposable parts

Precision matters in medical tooling.

Electronics Industry

Electronics manufacturers use repmold for:

-

Enclosures

-

Structural supports

-

Internal frames

Short product lifecycles make fast tooling important.

Consumer Goods Industry

Consumer goods producers use repmold for:

-

Packaging molds

-

Household product components

Repmold helps respond to market demand quickly.

Read Also: Understanding Soutaipasu in Simple Terms

Repmold Compared to Traditional Mold Making

Key Differences Explained

| Feature | Repmold | Traditional Mold |

|---|---|---|

| Lead time | Short | Long |

| Tooling cost | Moderate | High |

| Material waste | Low | High |

| Design changes | Easy | Difficult |

| Setup complexity | Lower | Higher |

Materials Commonly Used in Repmold

Material choice affects mold life and accuracy.

Polymer-Based Materials

Polymer systems capture detail well.

They are lighter than metal molds.

Composite Materials

Composite molds resist deformation.

They improve durability during repeated cycles.

Metal Inserts

Metal inserts strengthen high-stress areas.

They increase mold lifespan without full metal tooling.

Sustainability Benefits of Repmold

Repmold supports sustainable manufacturing goals.

Waste Reduction

Replication uses only required material.

Less cutting means less scrap.

Energy Efficiency

Repmold avoids heavy machining.

Lower energy use reduces production impact.

Tool Reuse

Partial mold replacement extends tool life.

This supports circular manufacturing.

Quality Control in Repmold Production

Quality control keeps molds consistent.

Measurement and Inspection

Technicians use measuring systems to confirm dimensions.

This prevents tolerance drift.

Surface Analysis

Surface quality affects part release.

Inspection ensures smooth production.

Repeatability Testing

Multiple production cycles confirm consistency.

Repeatability ensures stable output.

Limitations of Repmold

Repmold has defined boundaries.

Production Volume Limits

Very high-volume production favors steel molds.

Repmold suits low to medium volumes.

Material Compatibility

Not all plastics suit replication molds.

Material testing is necessary.

Dependence on Master Accuracy

Errors in the master transfer to the mold.

Accurate design is essential.

See More: Understanding the Keyword Antolohe

Repmold in Product Development

Repmold supports faster product launches.

Transition from Prototype to Production

Repmold converts validated prototypes into tools.

This shortens development timelines.

Market Testing Support

Short production runs test demand.

Tool changes remain simple.

Design Iteration Support

Localized mold updates allow fast revisions.

Full redesign is not required.

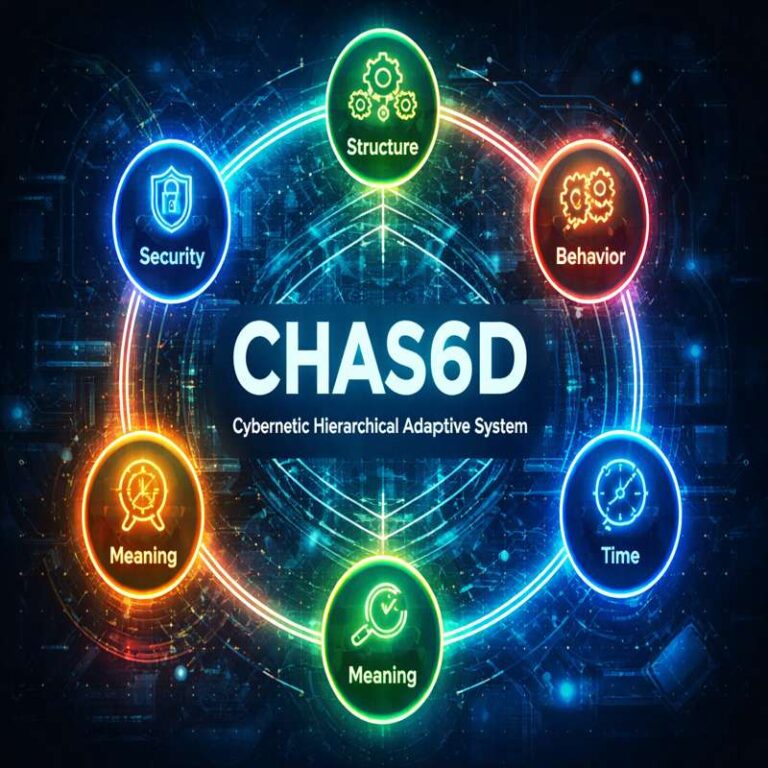

Digital Technologies Supporting Repmold

Digital systems improve repmold accuracy.

Simulation Tools

Simulation predicts mold behavior.

This reduces trial errors.

Automation Systems

Automation improves consistency.

Manual variation decreases.

Industry 4.0 aligns with repmold workflows.

Future Direction of Repmold

Repmold continues to evolve.

Material Innovation

Advanced composites improve heat resistance.

Tool life increases.

Process Automation

Automation reduces manual handling.

Consistency improves.

Digital Integration

Digital twins predict performance.

Quality improves before production.

Frequently Asked Questions About Repmold

What does repmold mean?

Repmold means creating molds by copying a master shape using replication methods.

Is repmold the same as rapid prototyping?

No.

Rapid prototyping creates test parts.

Repmold creates production molds.

Can repmold be used for injection molding?

Yes.

Repmold tools are commonly used in injection molding systems.

Is repmold suitable for mass production?

Repmold supports low to medium production volumes.

High-volume production often uses hardened steel molds.

Does repmold reduce manufacturing cost?

Repmold reduces tooling and setup costs.

It also lowers material waste.

What industries benefit most from repmold?

Automotive, medical, electronics, and consumer goods industries benefit most.

Conclusion

Repmold is a replication-based mold manufacturing process. It creates accurate, efficient, and reusable tooling. The method reduces lead time, cost, and waste. Industries use repmold to improve flexibility and speed. Repmold fits between prototyping and full-scale production. Its role continues to grow with digital and material advances.